Ut environmental de ambiente plastic pollutio permanere ad veliri, operam quae conversus ad redivivus et degradation of Polyethylene Terephthalate (pet), unus de maxime late usus plastics globally. In aqua utres, cibum continentia, textile fibris et packaging materiae, pet est notum est eius diuturnitatem - proprium facit ut et utile et inconueniens cum fit ut et utile et inconueniens cum fit ut et utile et inconueniens cum fit, ut et utile et inconueniens cum fit, ut et utile et inconueniens cum fit ut et utile et inconueniens cum fit ut et utilis et inconueniens cum fit ut arbitror. Hoc est ubi pet degradation catalysts venire in fabula.

Intellectus pet et degradation challenges

Polyethylene terephthalate (pet) Est thermoplastic polymer ex polymerization dehylene glycol et Terephthaic acidum. Eius optimum mechanicas et eget proprietatibus facere idealis ad vestibulum durare dolor products. Tamen, pet est eget stabilitatem etiam significat quod repugnant ad naturalem degradationem processibus, saepe perseverantes in letfills et maria ad saecula.

Traditional pet red redivivus modi - ut mechanica redivivus - involvere liquescens et reshaping in plastic, sed hi potest mendate material proprietatibus in tempore et saepe requirit maxime mundus initus materiae. Rebus redivivus offert via ad conteram pet tergum in in originali monomers, quae potest tunc esse repoberized in novus pet, conserveto qualis. Sed processus typice requirit altum temperaturis et pressuris faciens industria intensive.

Quid Pet degradation catalyst ?

A Pet degradation catalyst Numquid a eget substantia vel compositis, qui accelerat et naufragii de pet Polymer vincula in minor moleculis ut Misomers vel oligomenis. Hae catalysts inferioris industria obice de depolymerization reactionem, enabling pet ut indefinitum in inferioribus temperaturis, cum amplio efficientiam et reducitur environmental ictum.

Instead of freti in extrema scelerisque processibus, catalysts promovere ad CISTRUM ASTER vincula in pet structura, facilius hydrolysis , glycolysis , methanolysis aut enzymatic depolymerization - fretus in eget elit.

Genera Pet Degradation Catalysts

Sunt plures genera Catalysts propter pet degradation, et quisque ludit a unique partes fretus ad redivivus modum usus:

I. Alkaline Catalysts

In hydrolysis Hi includunt sodium hydroxide (Naoh) et potassium hydroxide (Koh), quod promovere naufragii de pet in conspectu aquae. Et reactionem typically cedit terephthaalio acidum (TPA) et ethylene Glycol (eg).

II. Metal, secundum Catalysts

Transitus metalla quasi Zinc acetate, Cobalt acetate, manganese acetate, and Titanium, secundum componit sunt communiter in glycolysis reactiones. Hae Catalysts Auxilium Cleane Petr in bis (II-hydroxyethyl) Terephthalate (Bhet), quod potest reddi ad synthesize novum pet.

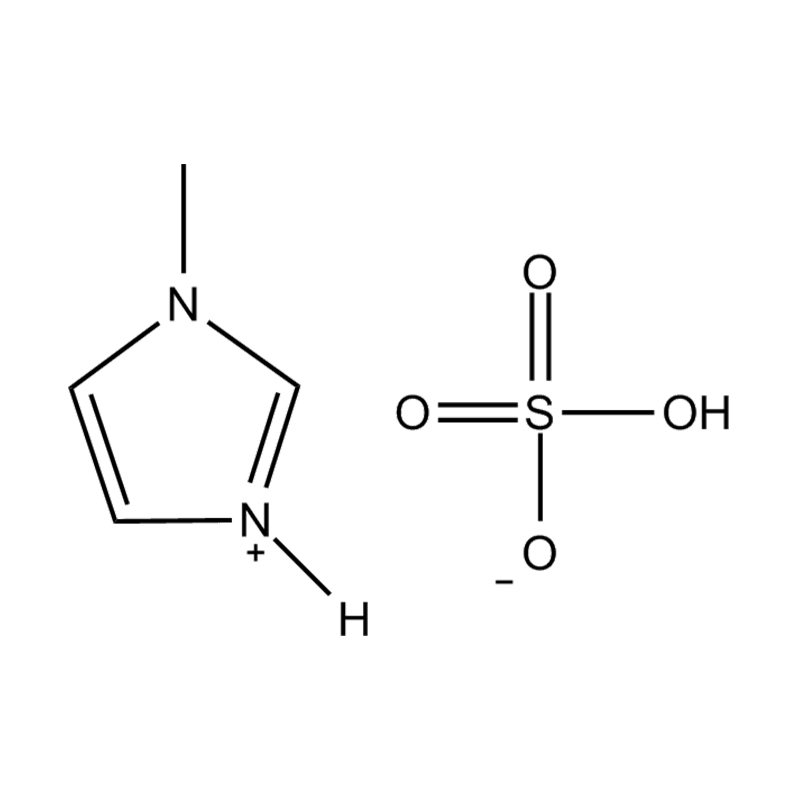

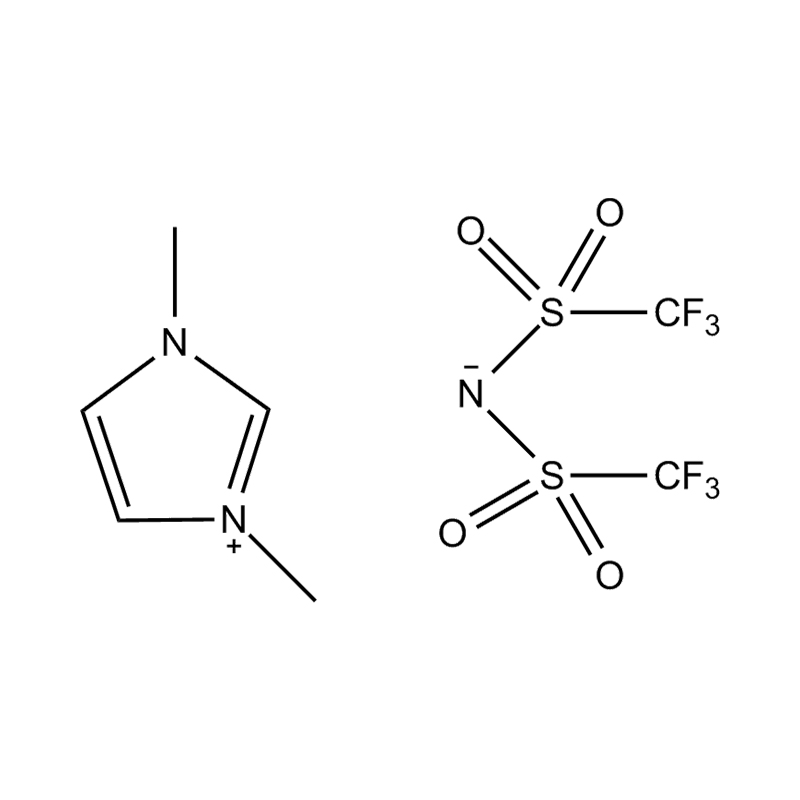

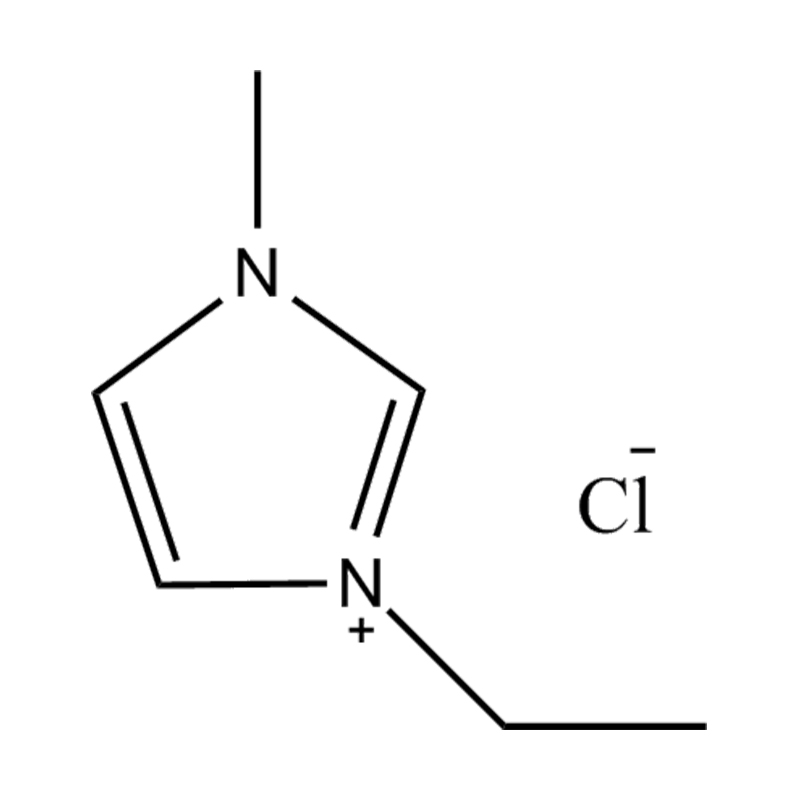

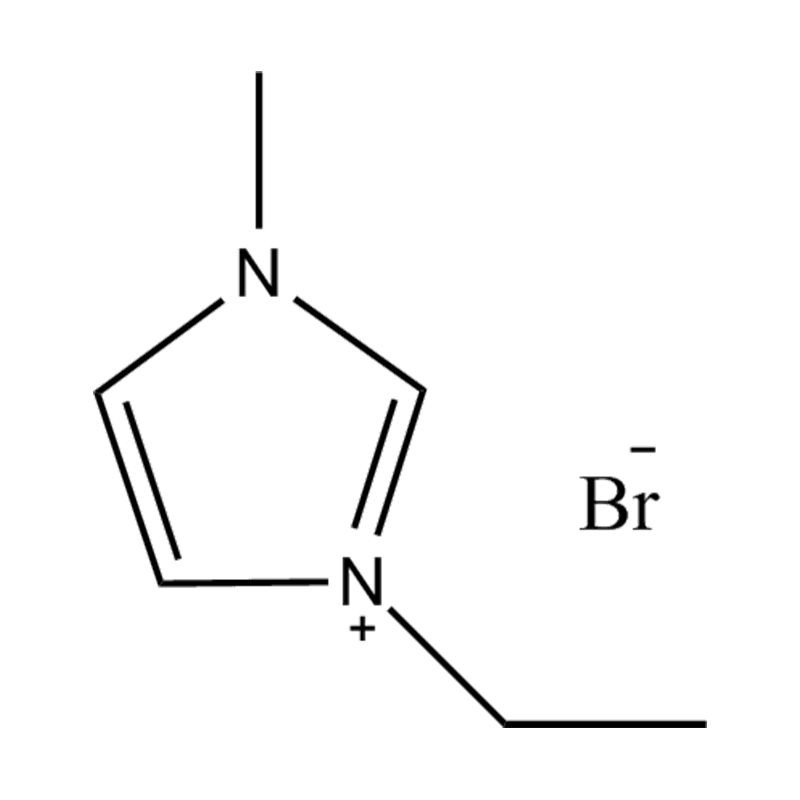

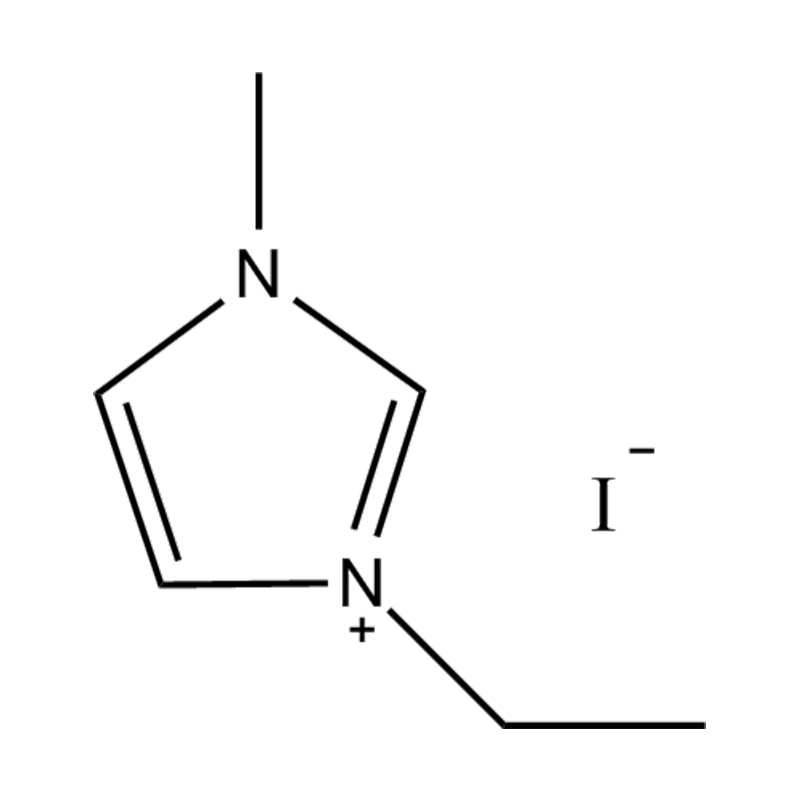

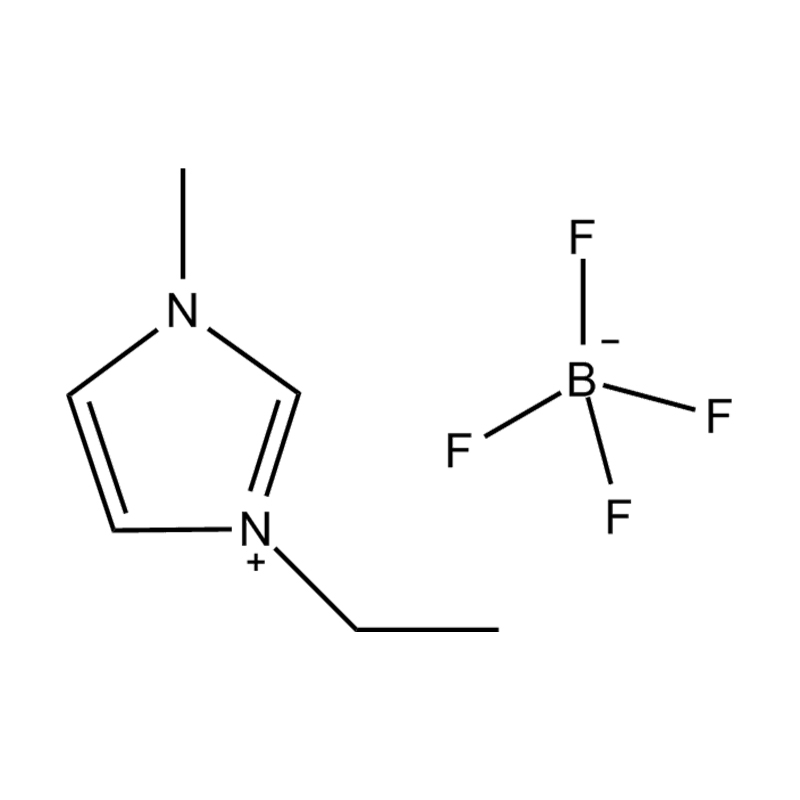

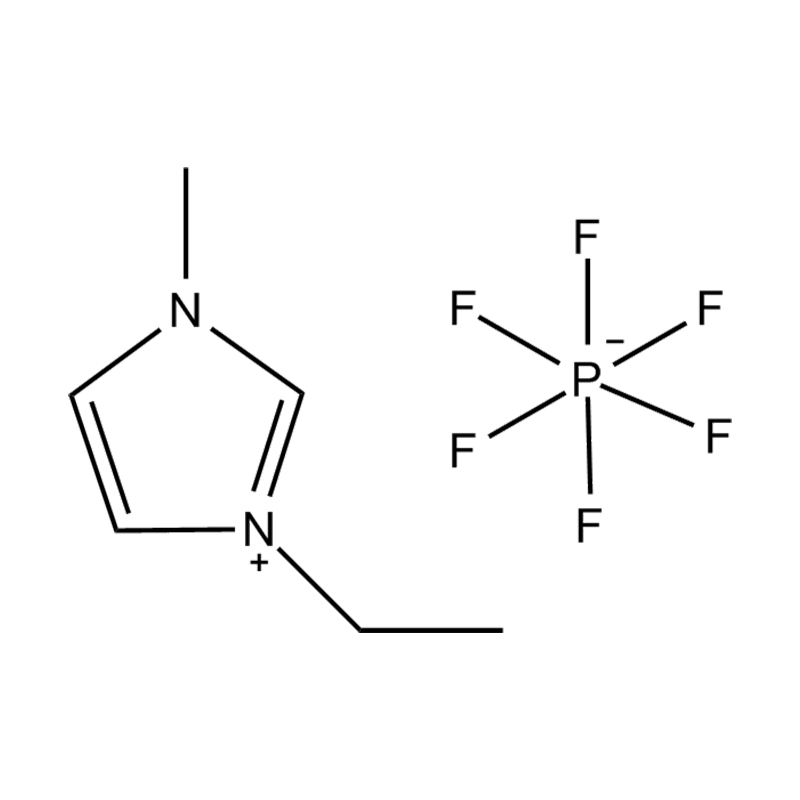

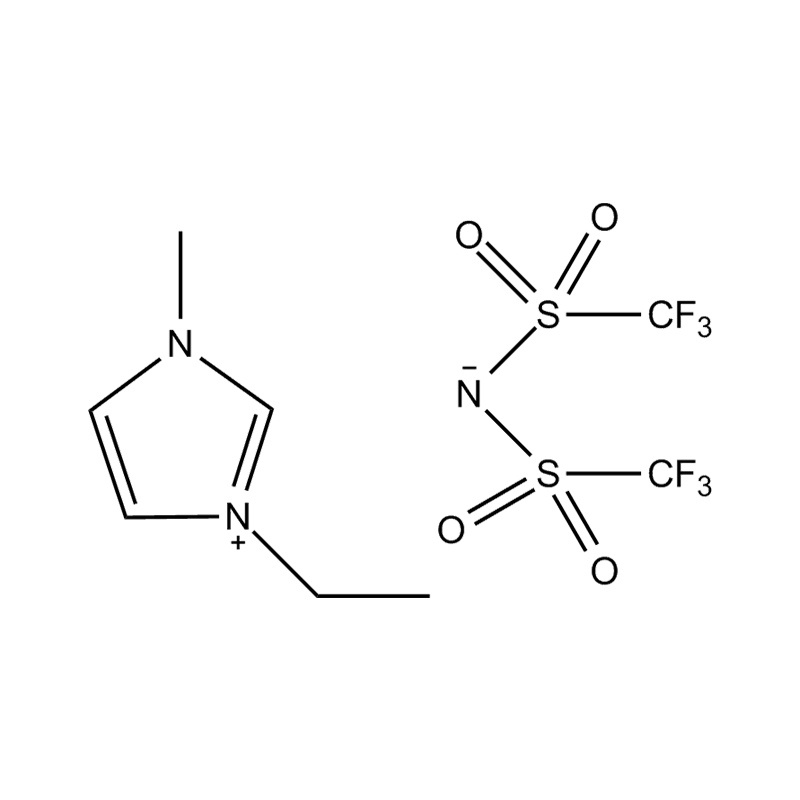

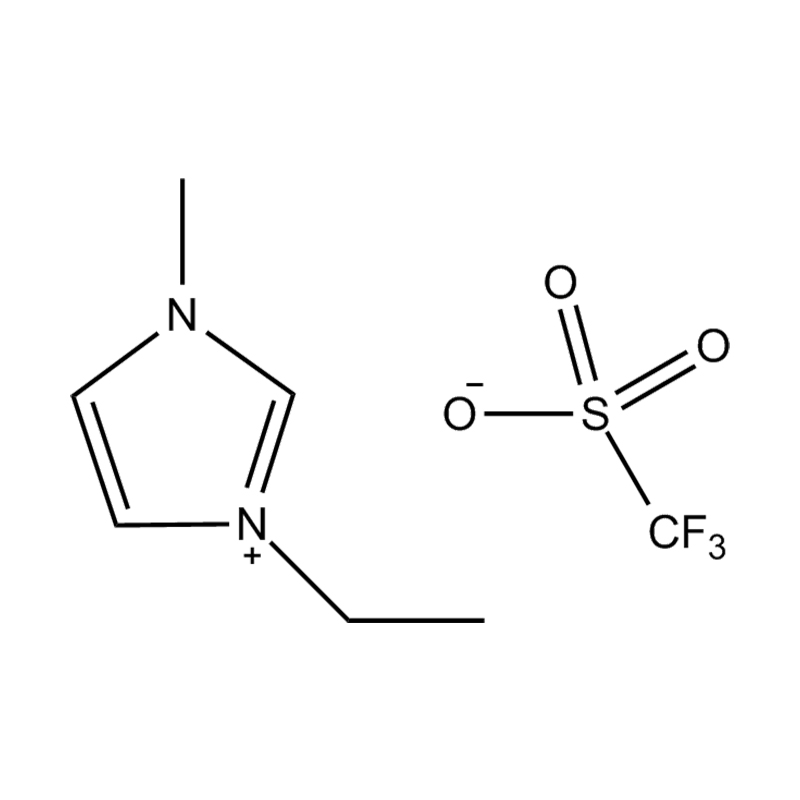

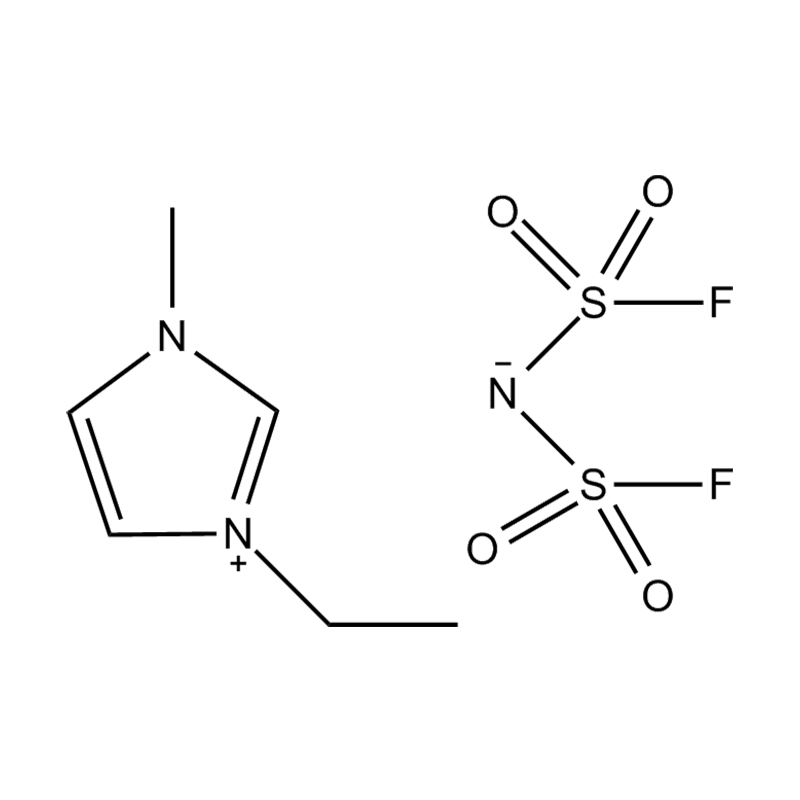

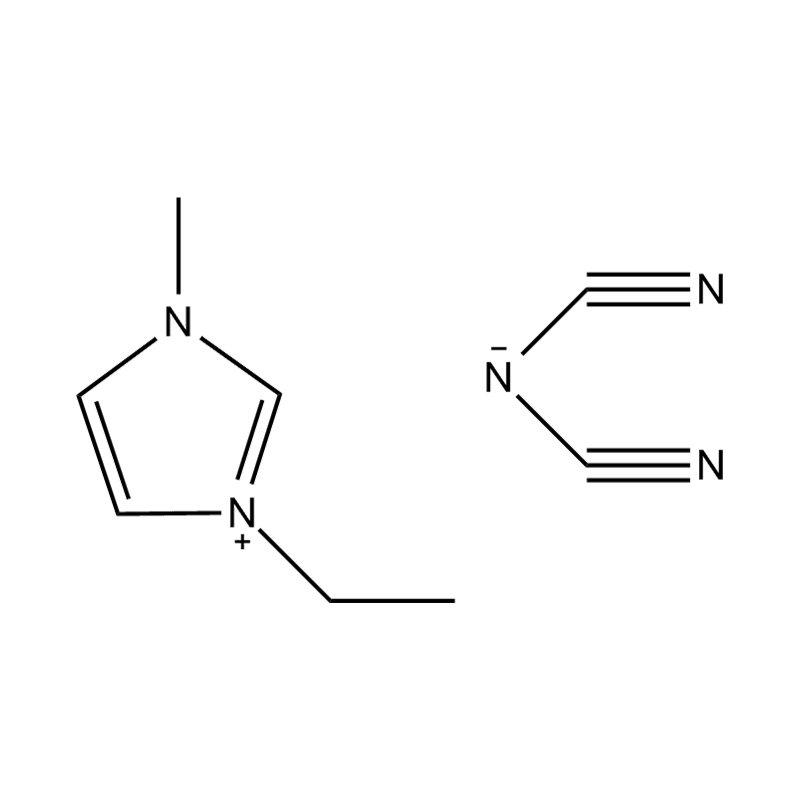

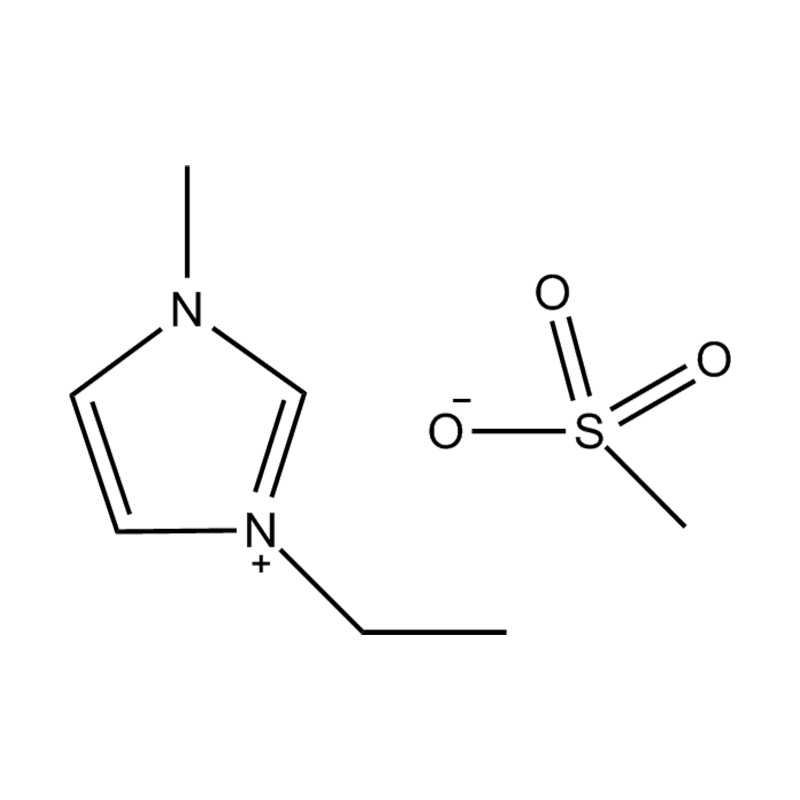

III. Ionic liquida

Ionicis liquida sunt sales in liquido statu potest agere ut utrumque solvents et catalysts. Offerimus altum selectivity et efficientiam in pet depolymerization, praesertim in methanolysis.

IV. Enzymatic catalysts

Enzymes ut Peto and Melsase , Ex Microbas sicut Ideonella sakaiensis , Potest biologically Deggrade pet sub mitis conditionibus. Quamvis adhuc primis gradibus commercialization, enzymatic degradation tenet promissionem Eco-amica, humilis-navitas pet redivivus.

V. organocatallsts

Organicum componit ut N-Heterocyclic Carbenes (NHCS) or Guanidines Potest etiam catalyze pet degradation, providing ad metallum-fundatur catalysts ut pose toxicity vel disposal quaestiones.

Quid pet degradation catalysts opus?

Function of a pet degradation Catalyst est infirmare et conteram in ASTER vincula, quae link pet monomars simul. Fit per

Reducing activation navitas : Catalysts providere an alternative reactionem iter cum inferioribus industria requisita.

Enhancing reactionem rates Et Catalyst accelerat ad Depolymerization processus, faciens non possibile ad industriae squamis.

Improving Selectivity : Quidam catalysts patitur pro targeted naufragii in specifica, summus valorem monomers, meliorem qualis est Recycled output.

Applications de pet degradation catalysts

Pet Degradation Catalysts sunt late in utroque Laboratory et Industrial Occasus ad Support:

Eget redivivus facilities : Nam producendo Monomers idoneam rursus polymerization in Virgin-gradus pet.

Textile redivivus : Effrego down polyester textilia in reusable components.

Plastic perditio administratione : Offering an alternative ad landfilling vel incineratio pet desertum.

Bioodegradation Studies : Enzymatic pet Degradation est ens investigentur pro on-site, Eco-amica degradation in marine et landfill conditionibus.

Beneficia usus pet Degradation Catalysts

Energy PECULIUM : Reducere opus summus temperatus operationes.

Material Recuperatio : Admitte plena naufragii in reusable Monomers.

Environmental ictum : Offer lautus alternatives ad mechanica redivivus aut ardenti.

VERSIO : Adaptable pro diversis redivivus techniques - glycolysis, hydrolysis, methanolysis, aut enzymatic itinera.

Challenges et futurum Outlook

Dum pet degradation catalysts offerre significant commoda, plures provocationes adhuc opus ad esse addressed:

Catalyst sumptus et convaluisset : Quidam metallum, secundum seu Ionic catalysts sunt pretiosa vel difficile ad separandum a finalis products.

Reactionem et cede : Achieving High reactionem efficientiam ad Industrial scale requirit ipsum.

Enzyme stabilitatem : Enzymatic Dauri Dragradation est promissum et indiget amplificata thermostability et scalability.

Contaminantium in vastum pet : Immundities potest impedire catalytic efficientiam et afficit puritatem recuperavit monomers.

Nihilominus, ongoing investigationis et innovation sunt propellentibus terminis, quae pet degradation catalysts potest consequi. Companies et Research Institutionum sunt operantes in Hybrid systems, combining enzymaticum et eget catalysis, aut per renewable materiae ad producendum sustineri catalysts.

Conclusio

Pet degradation catalysts Repraesentant potens instrumentum in global conatus tackle plastic perditio. Per enabling efficient, selectivam et scalable naufragii de pet Polymers in valuable Monomers, faciunt verum circularis plastic oeconomica magis potest. Sicut technologies permanere ad maturescere, et industries committere ad sustineri, partes harum catalysts mos tantum crescere magis centralis in figura futura plastic redivivus.

Utrum in eget plantis, textile recuperatio centers, aut biologicum systems, pet degradation catalysts sunt redefining quomodo nos administrare et reuse plastic - unum reactionem ad tempus.

中文简体

中文简体